Jewellery largely has a traceable history spanning back to the Neolithic age. Over time, the process of manufacturing has changed by leaps and bounds. Be it the traditional manufacturing or modern, the making of jewellery has remained a story in itself. In essence, it is not just a matter of creativity.

The process of manufacturing takes the combined talent of many individuals and technology. The progressively detailed sketches, to interlinking of sub-processes, to assembled pieces, there is a lot that goes into making a fine piece of jewellery. KGK adopted a fine manufacturing process, which has been refined from time to time,to translate every design into a piece of art. So in this blog, we present a small gist of the manufacturing process adopted by us. The process which is responsible for converting imagination into a reality.

Designing to Precision

The process starts with designing a blueprint of a design on a piece of paper. An idea of the end-product is communicated to a talented designer who then designs the sketch. Besides, for exact dimensions and specification of the piece, designs are also produced through CAD/CAM technology.

Modelling and Casting

A prototype of the design is created using 3D printers and other methods. A rubber mould is developed to produce the jewellery pieces. Further, to cast the article, the team pours the precious molten matter into the mould. Despite the use of technology in the casting process, the team constantly use their hands and eyes to avoid any defect due to technology.Since every piece at KGK is cast to connect emotionally with the users; it is checked for quality for the first time at this stage.

Filing and Polishing

Filing helps in removing excess metal and solder from the piece. The casting layer is removed using different tools like burrs. Plus, the team of craftsmen crave graphic decoration on jewellery pieces. The filing and polishing is done in an absolutely fault-proof manner.

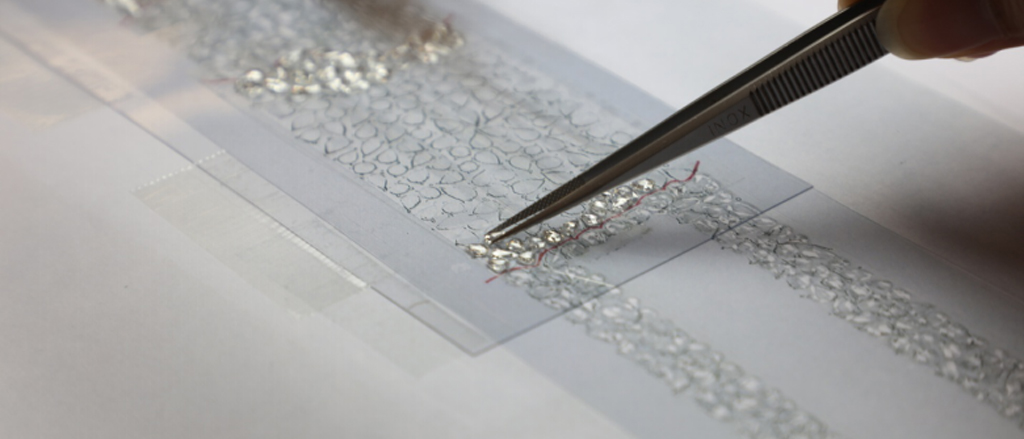

Embellishment and Settings

KGK believes that each piece deserves the care of skilled professionals only and therefore, the setting of the gemstones, embellishment, etc., is done by a skilled individual after the polishing and filing is done. The stones of the desired shape and size are cut and assorted into the piece.

Finishing

It requires immense patience, dedication, and a lot of work to produce an exclusive piece free from defects. So, for the piece to attain that soft and smooth finish, it is once again tested against several parameters before being delivered. They are finally made ready for selling.

This is how we offer a remarkably appealing collection to our clients globally. The manufacturing process is the soul and backbone of all our finest pieces. From a funky ring to a charming pendant, KGK group offers uniqueness in every piece through the introduction of unconventional processes throughout its manufacturing chain. Our manufacturing team comprises of engravers, toolmakers, stone cutters, and setters, who altogether breathe life in the pieces of jewellery. KGK is the place where imagination meets creativity through its state-of-the-art manufacturing process.